Renewable Diesel

Our research and working groups seek to inform users about renewable diesel, a practical drop-in alternative for reducing emissions in existing diesel vehicles and infrastructure, and facilitate its adoption.

RD 101

What is it?

Renewable diesel is a sustainable fuel made from organic materials like vegetable oils and animal fats.

It is chemically identical to petroleum diesel, and can be used directly in

diesel engines without modifications.

What are the Benefits?

Engine and Infrastructure Ready

Renewable diesel meets the ASTM D975 petroleum

diesel specification, meaning it works in existing diesel engines and fuel infrastructure

with no modifications

Lower Emissions

Not only does RD reduce both CO₂ and nitrogen oxides compared with petroleum diesel, certified pathways show renewable diesel averaging about a 65% lower carbon intensity than petroleum diesel

Flexible and Versatile

Renewable diesel can fully replace diesel or blend at any level. It can be produced from a wide range of feedstocks and is often made at facilities that also produce sustainable aviation fuel

Our Work with RD

In collaboration with Vermont Clean Communities, Maine Clean Communities holds a quarterly New England Renewable Diesel Working Group- a virtual forum that brings together industry partners, fuel suppliers, decision-makers, fleet managers, researchers, and clean-energy coalitions to advance the renewable diesel (RD) market across the region.

As New England seeks practical pathways to reduce transportation-sector emissions, this working group provides a collaborative space for information sharing, coordinated planning, and market development.

The group focuses on assessing current and future demand for renewable diesel in heavy-duty on- and off-road applications—including freight, municipal fleets, agriculture, marine, construction, and the ski industry.

Through stakeholder engagement, the series examines fueling requirements, infrastructure capacity, workforce training needs, cost-effectiveness, and supply chain considerations to support a scalable transition to low-carbon liquid fuels.

Each quarterly session highlights timely topics shaping the regional RD landscape.

Past meetings have covered foundational technical overviews, real-world fleet case studies, supply chain challenges, and early adoption experiences from public and private operators like Neste and the Massachusetts Port Authority.

By convening diverse stakeholders, the working group helps participants stay informed, collaborate on shared challenges, and shape the future of renewable fuels in New England. It aims to provide the insight and strategic alignment needed to accelerate RD deployment while complementing longer-term electrification initiatives.

Join Us For Our Next Working Group!

Watch Our Past Working Groups

Renewable Diesel vs Biodiesel

Biodiesel is made via transesterification- a chemical process that reacts animal fats, vegetable oils, or recycles cooking grease with an alcohol, usually methanol, producing fatty acid methyl esters (FAME)

By contrast, renewable diesel is made through hydrotreating where hydrogen is used to remove oxygen from feedstocks and form pure hydrocarbon chains.

Renewable diesel, like fossil diesel, is a pure hydrocarbon and can be used interchangeably with fossil-based diesel. That is why renewable diesel is often described as a “drop in” fuel.

Biodiesel is limited to specific maximum blends (usually 5 to 20 percent) and higher blends must be specially labeled, and their use is limited to compatible vehicles.

Biodiesel = an additive blended into diesel Renewable diesel = a replacement for diesel fuel

How its Made: Hydrotreating

Renewable diesel can be produced through several different technology pathways. Commercial production facilities predominantly use the hydrotreating pathway, with fats, oils, and greases as the most common feedstocks: Hydrotreating converts these vegetable oils, animal fats, and waste oils into high-quality, hydrocarbon-based fuels.

The process involves adding hydrogen to the feedstock under high pressure and temperature conditions, leading to the removal of unwanted elements and the conversion of triglycerides into paraffinic hydrocarbons

Carbon Intensity

A carbon intensity (CI) score measures how much greenhouse gas (GHG) emissions are produced per unit of energy over the entire lifecycle of a fuel.

In other words, it answers: “How much carbon does this fuel create from start to finish?”

That lifecycle includes: extracting or growing the feedstock, processing/refining it, transporting it, burning it in an engine.

Even if two fuels have the same tailpipe emissions (like diesel vs. renewable diesel), their CI scores can be very different because their upstream emissions differ.

Renewable diesel made from waste fats, for example, typically has much lower lifecycle emissions than petroleum diesel.

CI scores are usually expressed as grams of CO₂-equivalent per megajoule (gCO₂e/MJ)

Renewable Diesel delivers significant lifecycle GHG reductions compared with petroleum diesel and biodiesel.

Conventional diesel has an average lifecycle carbon intensity of ~100 gCO2e/MJ, serving as a benchmark for evaluating low-carbon fuel alternatives.

Soy-based biodiesel (the most common BD feedstock) has a typical CI range of 50-70 gCO2e/MJ. Produced through transesterification, its energy-efficient processing uses relatively little energy output. However, its CI benefits are limited by the agricultural emissions associated with soy cultivation.

Renewable diesel is produced through hydrotreating, gasification, or other thermochemical processes that create a hydrocarbon fuel chemically identical to petroleum diesel, and its CI depends heavily on the feedstock used to produce it.

Soy or Corn Oil: ~40-60 gCO2e/MJ

Though soy or corn oil based renewable diesel carries higher upstream agricultural emissions, the hydrotreating process and resulting chemical makeup receives a lower CI score than petroleum diesel and generally lower than soy biodiesel.

Tallow or Used Cooking Oil (UCO): ~15-40 gCO2e/MJ

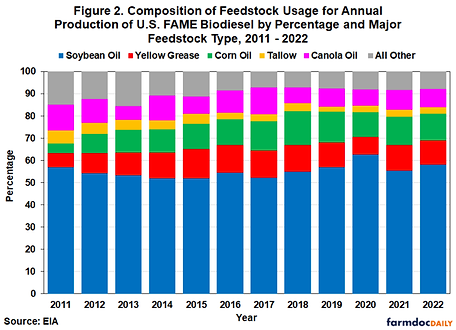

Feedstock Composition for U.S. Biodiesel and Renewable Diesel

RD in the Northeast

Suppliers in New England

Sprague Energy

Describe your service here. What makes it great? Use short catchy text to tell people what you offer, and the benefits they will receive. A great description gets readers in the mood, and makes them more likely to go ahead and book.

Broco Energy

Describe your service here. What makes it great? Use short catchy text to tell people what you offer, and the benefits they will receive. A great description gets readers in the mood, and makes them more likely to go ahead and book.

Global Partners

Describe your service here. What makes it great? Use short catchy text to tell people what you offer, and the benefits they will receive. A great description gets readers in the mood, and makes them more likely to go ahead and book.

Fleet Spotlights

This is your Team section. Briefly introduce the team then add their bios below. Click here to edit.

_edited.png)